How a GEO Agency Redefines AEO and SEO for the Generative Search Era

What is a GEO Agency and How Does It Differ from Traditional SEO and AEO?

A GEO agency specializes in Generative Engine Optimization—optimizing brand visibility within AI-generated responses produced by large language models like ChatGPT, Google’s Search Generative Experience (SGE), Perplexity, and Claude. These agencies focus on ensuring AI systems correctly understand, reference, and cite a brand’s content when synthesizing answers for users.

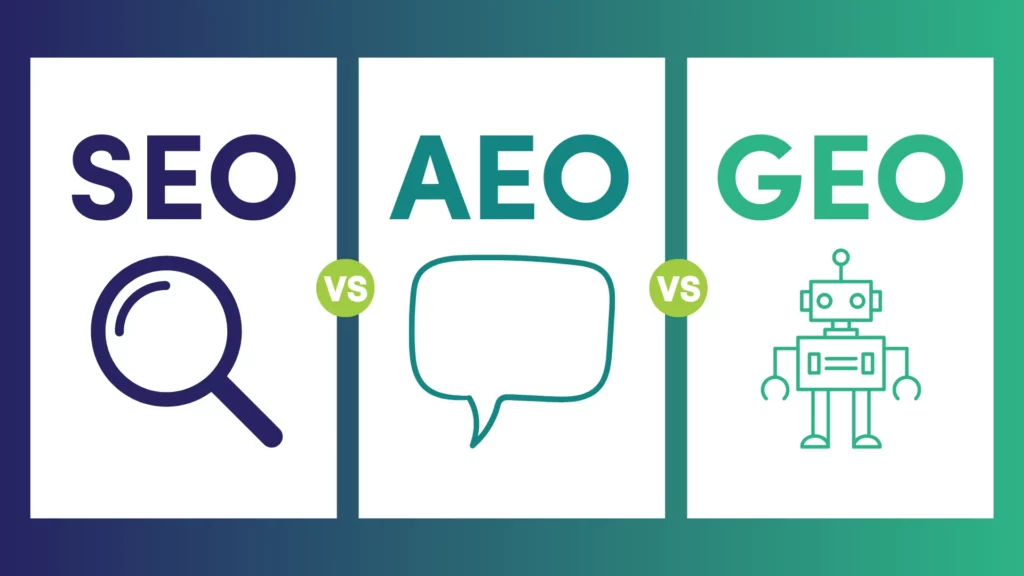

The GEO agency definition centers on a fundamental shift in how content reaches audiences. Traditional SEO relies on keyword-based ranking strategies, backlink profiles, and user engagement metrics to secure positions on search engine results pages. GEO agencies work differently—they optimize for how AI crawlers interpret content and how generative models incorporate that information into synthesized knowledge outputs.

Key Differences Between Traditional SEO and GEO

Traditional SEO vs GEO reveals stark operational differences:

- SEO: Targets ranking positions through keywords, meta tags, and link building

- GEO: Influences AI comprehension through structured content, semantic markup, and E-E-A-T signals

- SEO: Measures success by page rankings and click-through rates

- GEO: Tracks brand mentions within AI-generated responses across multiple platforms

The Role of AEO Optimization

AEO optimization serves as a bridge between these approaches. Answer Engine Optimization specifically targets featured snippets and AI overviews—the boxed answers appearing at the top of search results. AEO focuses on concise, direct answers to specific queries.

The Expansion of GEO Beyond AEO

GEO expands beyond this narrow scope. While AEO aims for a single featured snippet, GEO agencies work to embed brand authority across the broader knowledge synthesis performed by generative AI tools. This means appearing in conversational AI responses, voice assistant answers, and multi-source synthesized outputs that combine information from numerous sources into coherent narratives.

The distinction matters because AI-powered answer engines don’t simply extract snippets—they generate new content by understanding context, synthesizing multiple perspectives, and creating personalized responses based on nuanced, conversational queries.

Why Is the Generative Search Era Changing the Optimization Landscape?

The generative search era represents a fundamental shift where AI systems synthesize information from multiple sources to create original responses rather than simply ranking existing web pages. This transformation disrupts decades of search engine optimization built around link equity and keyword placement.

The Decline of Traditional Link-Based Rankings

Search behavior now bypasses the traditional “10 blue links” model. Users increasingly receive direct answers from AI platforms like ChatGPT, Google’s Search Generative Experience (SGE), Perplexity, and Claude without clicking through to source websites. Gartner research predicts a 25% reduction in traditional search engine traffic by 2026 as AI-powered search adoption accelerates. This means brands can no longer rely solely on backlink profiles and domain authority to capture visibility.

How Large Language Models Transform Search Behavior

LLMs process queries differently than traditional search algorithms:

- They interpret conversational, context-rich questions spanning 20-50 words instead of 2-3 keyword phrases

- They synthesize information across multiple sources to generate coherent, personalized answers

- They prioritize content structure and semantic meaning over keyword density

- They evaluate expertise signals and trustworthiness markers embedded within content

The AI-powered search evolution changes what “ranking” means. Instead of competing for position #1 on a results page, brands must optimize to be cited and referenced within AI-generated knowledge synthesis. Google SGE, for example, pulls information from 5-10 sources to construct each response, creating new competition dynamics where multiple brands can gain visibility within a single answer.

This paradigm shift requires optimization strategies that help AI systems understand, extract, and attribute information correctly—the core mission of GEO agencies navigating the generative search era impact. To adapt to this new landscape, a comprehensive AI search optimization strategy is essential.

How Do GEO Agencies Optimize Content for Generative AI Platforms?

Content optimization for generative AI begins with question-based keyword research that mirrors how users interact with AI chatbots and virtual assistants. GEO agencies analyze conversational query patterns—typically longer, more specific questions than traditional keyword searches—to identify the exact phrasing and context that triggers AI-generated responses. This research uncovers the natural language patterns that large language models recognize and prioritize when synthesizing answers.

Structuring Content for Machine Comprehension

Semantic HTML for AI forms the backbone of GEO content architecture. Agencies structure articles with hierarchical heading tags (H1-H3) that create clear information pathways for AI crawlers to follow. Each heading answers a specific question, with supporting content organized in short paragraphs under 80 words that AI systems can easily parse and extract.

Key structural elements include:

- Mini tables of contents for longer articles that help AI identify relevant sections quickly

- FAQ sections marked with schema.org/FAQPage markup to signal question-answer pairs

- Semantic tags like

<strong>and<em>to emphasize important concepts - Ordered and unordered lists that break down complex information into digestible chunks

Implementing Structured Data Protocols

Structured data for AI understanding enables precise information extraction by generative platforms. GEO agencies implement Article markup to define content type, authorship, and publication dates. FAQ schema explicitly labels questions and their corresponding answers, making it effortless for AI models to identify authoritative responses. This machine-readable formatting ensures that when ChatGPT, Google SGE, or Perplexity synthesizes an answer, they can accurately attribute information to the source while maintaining context and meaning.

What Technical Strategies Do GEO Agencies Implement to Enhance Crawlability and Performance?

GEO agencies prioritize crawler access control to ensure AI systems can efficiently discover and interpret content. This begins with managing specialized directives through robots.txt and the emerging llms.txt files, which explicitly guide AI crawlers on which pages to index and how to process them. Unlike traditional search bots, LLM crawlers require clear signals about content priority and access permissions to build accurate knowledge representations.

The llms.txt file represents a new standard specifically designed for AI training data collection. GEO agencies configure these files to:

- Specify which content sections are most valuable for AI synthesis

- Indicate preferred citation formats for brand references

- Control access to proprietary information versus publicly shareable knowledge

- Define crawl rates that balance visibility with server performance

Site speed optimization becomes critical as AI crawlers evaluate content quality partly through performance metrics. GEO agencies implement aggressive caching strategies, compress images using next-generation formats like WebP, and leverage content delivery networks (CDNs) to reduce latency across geographic regions.

JavaScript presents a significant barrier to AI crawlability. Many LLM crawlers struggle with client-side rendering, missing content hidden behind JavaScript execution. GEO agencies address this by:

- Converting dynamic JavaScript elements to server-side rendered HTML

- Implementing progressive enhancement where core content loads without JavaScript dependencies

- Using static site generation for content-heavy pages

- Ensuring critical text remains accessible in the initial HTML payload

Performance monitoring extends beyond traditional metrics. GEO agencies track Core Web Vitals while simultaneously measuring how quickly AI crawlers can parse page structure. They audit mobile responsiveness since many AI assistants operate on mobile-first platforms, ensuring content adapts seamlessly across devices without sacrificing semantic clarity or structural integrity that AI systems depend on for accurate information extraction.

How Do GEO Agencies Maintain Brand Consistency Across Evolving AI Search Platforms?

1. Establishing Unified Content Standards

Brand governance in GEO requires establishing unified content standards that AI systems can reliably recognize and reproduce. GEO agencies implement centralized style guides that define terminology, voice patterns, and messaging frameworks across every digital touchpoint where generative AI might encounter brand content.

2. Applying the E-E-A-T Framework

The E-E-A-T framework application becomes the foundation for this consistency work. Agencies audit existing content to ensure every piece demonstrates:

- Expertise through detailed explanations backed by data and research

- Experience via first-hand accounts, case studies, and practical examples

- Authority established through author credentials, citations, and industry recognition

- Trustworthiness reinforced by transparent sourcing, regular updates, and clear contact information

This focus on E-E-A-T is crucial as it also plays a role in guiding authorship expertise which directly impacts SEO performance. A deeper understanding of how E-E-A-T is guiding authorship expertise and SEO can further enhance the effectiveness of these strategies.

3. Understanding AI Models

AI models synthesize information from multiple sources before generating responses. When a brand’s messaging varies across platforms—using different product names on social media versus the website, or inconsistent service descriptions across blog posts—LLMs struggle to form coherent representations. This fragmentation dilutes brand presence in AI-generated answers.

4. Creating Content Templates

GEO agencies create content templates that maintain structural consistency while allowing creative flexibility. These templates ensure that key brand terms appear in predictable patterns, making it easier for AI systems to identify authoritative sources. The agency might standardize how product features are described, how company history is presented, or how customer problems are framed across all content channels.

5. Conducting Regular Content Audits

Regular content audits identify inconsistencies that could confuse AI crawlers. Agencies track how brand information appears in AI responses, then trace discrepancies back to conflicting source content. This feedback loop enables continuous refinement of brand messaging to align with how generative platforms actually interpret and cite the brand.

6. Focusing on Author Profiles

Author profiles receive particular attention, as AI systems increasingly evaluate content credibility through contributor expertise. Agencies ensure author bios remain current, detailed, and linked across platforms to strengthen the expertise signals that influence AI citation decisions.

How Do GEO Agencies Measure Performance in Generative AI Environments?

GEO agencies use generative AI analytics tools to track how often and in what context brands appear within AI-generated responses. These specialized platforms monitor citations, sentiment, and positioning across multiple AI systems including ChatGPT, Perplexity, Google SGE, and Claude—providing visibility that traditional analytics cannot capture.

Why Traditional SEO Metrics Aren’t Enough

Brand visibility tracking in AI answers requires fundamentally different metrics than conventional SEO. Instead of monitoring page rankings or click-through rates, GEO agencies measure:

- Citation frequency: How often AI systems reference the brand when answering relevant queries

- Answer positioning: Whether the brand appears in primary answers versus supplementary context

- Source attribution accuracy: If AI platforms correctly attribute information to the brand

- Sentiment analysis: The tone and context in which the brand is mentioned within synthesized responses

- Query coverage: The breadth of topics where the brand appears as an authoritative source

How Agencies Gather Data

These tools use API integrations with AI platforms where available, combined with systematic query testing across hundreds of relevant prompts. Agencies create query matrices that reflect actual user conversations—tracking how brands perform across different question types, contexts, and AI platforms.

What the Data Reveals

Real-time dashboards visualize brand presence patterns, identifying which content pieces AI systems favor and which knowledge gaps exist. This data reveals opportunities to strengthen authority in specific topic areas or adjust content structure for better AI comprehension.

Staying Ahead with Proactive Monitoring

Some agencies develop proprietary monitoring systems that automatically test brand visibility across rotating query sets, generating alerts when citation patterns shift. This proactive approach helps brands respond quickly to changes in how AI systems interpret and reference their content. Visit https://happyhamstercomputers.com/how-businesses-can-leverage-geo-and-aeo-strategies-to-dominate-ai-generated-results/ to get how businesses can leverage GEO and AEO strategies to dominate AI-generated results.

Understanding the Competition

The measurement framework also includes competitive analysis, showing how rival brands appear in similar AI-generated answers. This comparative intelligence guides strategic content investments and identifies white space opportunities where brands can establish stronger AI visibility.

Conclusion

The generative search era demands a fundamental rethinking of digital visibility strategies. Brands that continue relying solely on traditional SEO tactics risk becoming invisible in AI-generated responses that increasingly shape consumer decisions and information discovery.

A GEO agency redefines AEO and SEO by bridging the gap between conventional optimization and the requirements of large language models. This integration creates a resilient strategy that maintains visibility across traditional search engines, featured snippets, and AI-synthesized answers.

The shift isn’t temporary—AI-powered search experiences are rapidly becoming the default interface for information retrieval. Organizations that invest in GEO capabilities now position themselves to capture attention in this transformed landscape, where being cited by AI systems matters as much as ranking on page one.

Adapting to generative search means embracing structured content, semantic clarity, and brand consistency as foundational elements rather than optional enhancements. The question isn’t whether to optimize for AI platforms, but how quickly your brand can evolve to meet this new reality.